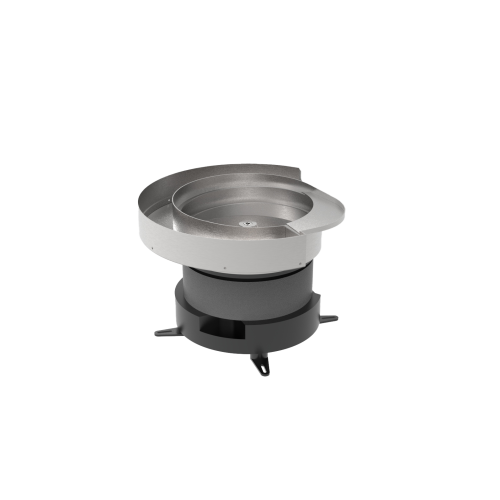

Vibratory bowl feeders are sophisticated devices with precision processing that are commonly used in automated production. Bowl feeders efficiently handle parts of various sizes, weights, and materials.

Thanks to orientation elements located inside or outside the vibratory bowl feeder, the vibratory feeder itself can transport parts reliably, and orient them correctly. Compressed air can be used for even more precise positioning. The feeder hopper is located on a bowl vibrator (drive), which guarantees optimal dosing of parts.

The size, material and surface finish per the individual specifications provided by each client are taken into consideration in the production of vibratory hoppers.

We manufacture the hopper part of the vibratory feeder using 1.4301 and 1.4404 stainless steel. 1.4404 stainless steel is used for applications in the food and pharmaceutical industries. Vibratory bowl feeder hoppers may also be made from EN AW-5754 (AlMg3) class aluminium alloy.

Orientation of bowl feeder:

We manufacture hoppers for bowl vibrators (drives) using 1.4301 and 1.4404 stainless steel. 1.4404 stainless steel is used for applications in the food and pharmaceutical industries. Vibratory feeder hoppers may also be made from EN AW-5754 (AlMg3) class aluminium alloy.

Hoppers are classified into three basic categories:

Depending on the type of material that is to be transported, it is critical to select the type of hopper that will meet specific requirements. We can adapt the hoppers to the customer's needs in terms of shape, size and gradients on transport routes.

vibratory bowl drive

controller

surface treatments and sprays

Gallery