Surface treatments for vibratory feeders are applied to the internal components of bowl feeders.

Surface treatments we apply:

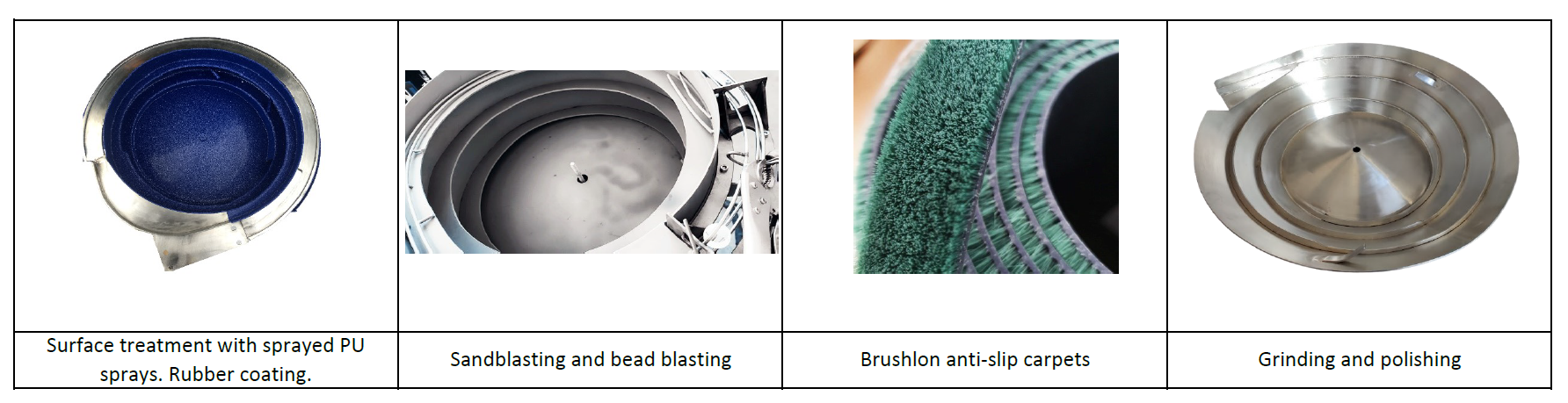

Surface treatment with sprayed PU sprays. Rubber coating.

Rubberising a vibratory feeder reduces noise, especially when it comes to larger and heavy parts. The main task of the rubber coating is to reduce the wear of the feeder part and the fed parts themselves. It also extends the life of the vibratory feeder. An anti-slip additive can be applied to the rubber coating, which prevents the parts from sliding backwards and improves the movement of the part in the feeder.

Sandblasting and bead blasting

Sandblasting unifies the appearance of the entire vibratory feeder. The main advantage of sandblasting is the gentle roughening of the surface. This is suitable for parts that have a small contact area with the feeder track and a tendency to backtrack along the feed line.

Brushlon anti-slip carpets

Brushlon anti-slip carpets are applied in the inner part of the bowl feeder. The main task of Brushlon carpets is to reduce noise, protect against wear, and prevent the part from backtracking along the feed line. The small bristles are tilted at a certain angle, which prevents any backward movement of the part. Brushlon has a wide range of uses for both small and large parts.

Grinding and polishing

Grinding and polishing of vibratory bowl feeders unifies the appearance of the entire device. This is primarily applied in the food and pharmaceutical industries. The clean and smooth surface is easy to clean and maintain. It also prevents the contamination of parts fed through the feeder.